You Hope You Have Competent Pilots Flying

Twenty years ago, a panel on my 747 wing broke off. I was a 747 Second Officer at the time. We had just departed Anchorage headed for Tokyo. During the walkaround I had asked about over-servicing one of the landing gear struts, and maintenance confirmed it was within limits We took off, gear up, and Boom! It felt like a sledge hammer hit the side of the aircraft and then she shook violently.

The first thought was it the gear due to the timing of retraction. The FO called maintenance. I went down stairs to see if any of the cargo was an issue. As I returned the guys were cycling the landing gear. They were also cleaning up the plane, meaning bringing flaps up. When the gear and flaps were retracted, the vibration stopped.

We pressed onto Tokyo, and we even made fuel. Meaning... we did not burn what we planned, but less than. In hindsight, it's hard to believe with a hole in the wing we would not burn more. When we began configuring I said, "Do you feel that?" I could feel the vibration in my feet. As we slowed, it got worse. We landed with flaps 15 and kept her at higher speed.

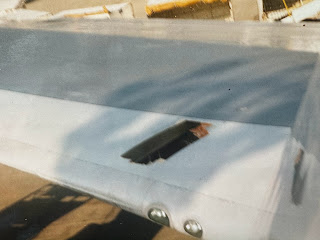

Not until we landed and I climbed a ladder, did I see the hole. To put it into perspective, the wing is about 48 feet at that area. This hole was every bit of 6 feet long, and a foot wide.

This week the world watched the video of the B757 leading edge falling apart and the ensuing emergency landing. A question media asked, "Is this a maintenance issue" the answer is "NO". This is an age related issue. Equipment breaks. Old airplanes fall apart.

Plastic parts!

ReplyDeleteOf which Duct Tape was made. :)

ReplyDelete